-40%

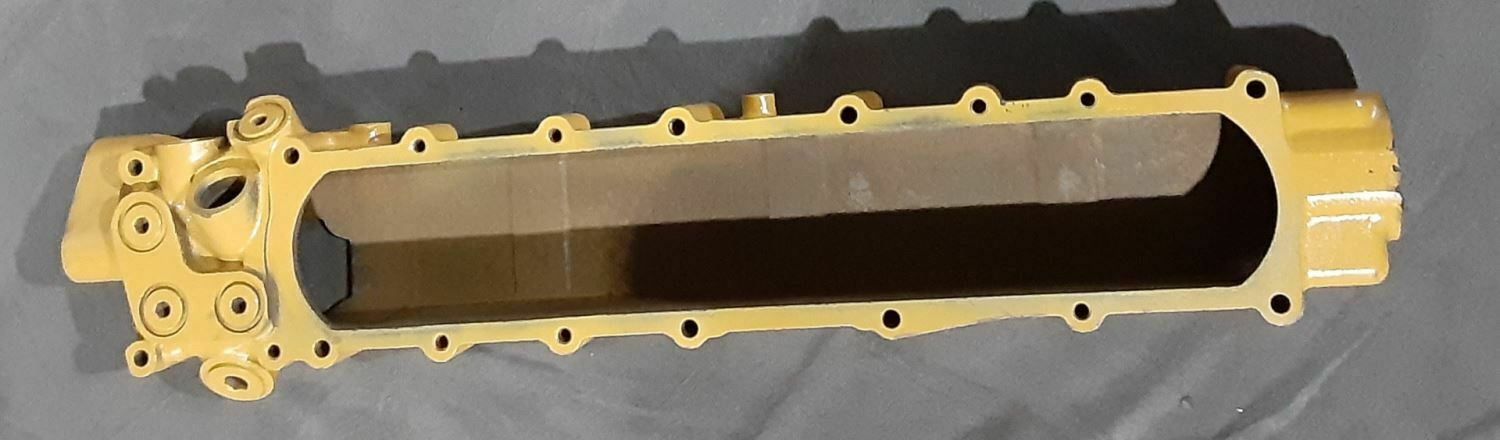

Spinner II Centrifugal Oil Purifier Model 25 Part Number 71957 .8 GPM

$ 233.37

- Description

- Size Guide

Description

**NOT INCLUDED: Hoses and Fittings To Install. Each situation is different.For Oil Sump Capacity of up to about 9 to 12 Gallons or smaller.

Remove particles down to .1 micron thus increasing engine life and oil change interval saving $$

Does NOT Remove water

Oil Supply to Centrifuge:

Oil supply should, in general, be taken from

the highest pressure, hottest source available

immediately downstream of the lube pump.

A 3/8

” pipe (or #6 hose) supply line should be

used. The unit’s supply port is a #6 female

SAE O-ring design (

9/16

-18 straight thread).

Preferred pressure is 60 to 80 psig but the

Spinner II centrifuge will operate efficiently

at 35 to 90 psig. The idle Cut-Out Valve (COV)

allows oil to enter the unit only when supply

pressure exceeds 20 psi.

Clean Oil Return to Sump

Gravity Drain:

The Spinner II centrifuge

must be close-coupled to the sump with an

unrestricted 1” ID (or #20 hose) drain returning

above the normal sump oil level. The drain

line must be sloped downward from the

centrifuge outlet and be free of sharp bends

or traps. On many engines, an access plate

into the gear train or crankcase can be modified

to provide a suitable drain opening as well as

sturdy mechanical support. Be sure the sump

side of the drain opening is clear and that the

drain oil does not impinge on moving parts of

the engine.

Mechanical Considerations:

Spinner II centrifuges are high–speed devices

and should be securely mounted to prevent

excessive vibration. Operation up to 10 or 15

degrees from vertical is permitted. Further

installation guidelines are provided in Spinner II

diagram A1-5154.